Utilising proprietary technology to create innovative new solutions

We believe that our product offerings are capable of having a game-changing impact in a broad variety of industry sectors through our subsidiaries:

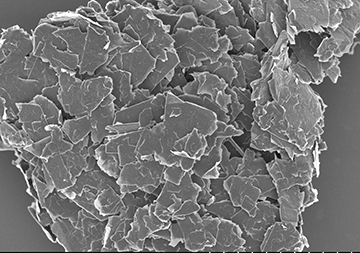

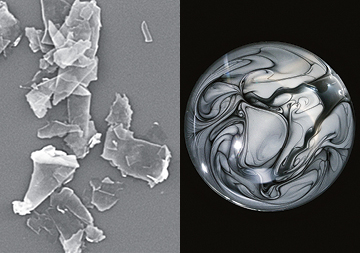

2-DTech Limited, a spin-out from the University of Manchester, the birthplace of graphene and home to the Nobel Prize winning academics Geim and Novoselov, specialises in the supply of graphene products and the transfer of fundamental science to applied technology.

Polygrene – our new graphene enhanced polymer range

Cambridge Graphene Limited, a spin-out from Cambridge University, supplies novel graphene inks and develops graphene/2D materials technology and applications.

Based in Seoul, South Korea VKL specialises in the development of CVD graphene.

Based in Longhope, Gloucestershire is the Group's dedicated graphene manufacturing business.

Gnanomat S.L. based in the Parque Científico Madrid, Spain, is a company capable of utilising Versarien’s graphene products in an environmentally friendly, scalable production process for energy storage devices.

Versarien Graphene Inc, based in Texas, is the newly incorporated sales business for the UK’s graphene products.

Beijing Versarien Technology Limited is the wholly owned Chinese foreign entity that will form the base for expansion activities in China.

Using Versarien’s existing graphene manufacturing capabilities, AAC Cyroma will have the ability to produce graphene enhanced plastic products.

Total Carbide Limited is a leading European manufacturer of sintered tungsten carbide primarily for arduous environment applications in the oil and gas industry. Created in 1950, the company has a wealth of experience and focuses on world‑class product quality through the latest engineering practices.

A continual deal flow entirely establishing new licence arrangements with research institutions or by identifying embryonic companies in early stages of development where intellectual property fits with our definition of advanced materials technology.

Applying the management team’s experience to developing and commercialising the advanced materials technology.

Providing working capital facilities either from existing reserves, its public listing or via banking facilities.

Providing the plant and equipment to get into production either via its existing production facilities or by funding new facilities.

Versarien plc seeks to capitalise on innovative IP, transforming it into commercially viable products that can tackle the technological challenges faced by modern manufacturers.

Our objectives for the current financial year are to: